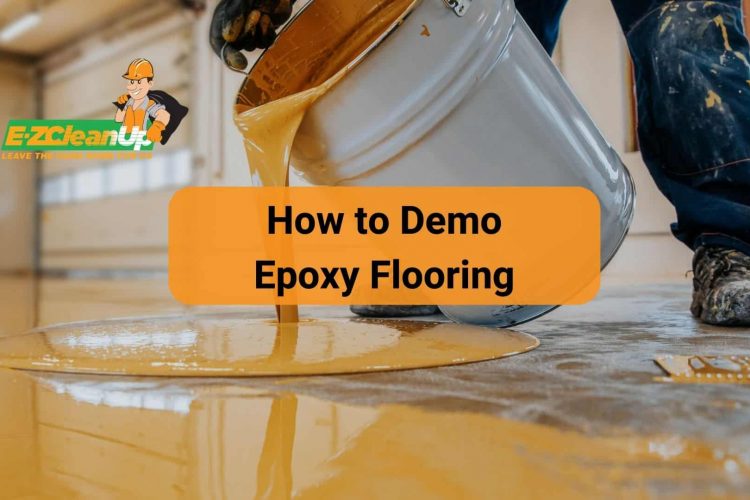

To demo epoxy flooring, employ mechanical methods such as using putty knives on cured surfaces and grinders for thin layers. You can also opt for chemical treatments to dissolve the adhesive and protect the underlying concrete’s integrity.

To learn more about each method of how to demo epoxy flooring, read on.

Mechanical Methods for Epoxy Removal

Given epoxy’s strong adhesive qualities, removing it correctly is crucial to avoid damage to the underlying concrete and ensure a smooth process for whatever comes next. Removing epoxy flooring using mechanical methods can be an effective way to clear away old or unwanted coatings.

Using a Putty Knife or Chisel for Cured Epoxy

For areas where the epoxy has cured and become hard, a putty knife or chisel can be used to manually scrape off the coating. This approach is labor-intensive but can be effective for small areas or for removing stubborn patches of epoxy.

The technique involves applying a consistent pressure and angle to lift the epoxy without damaging the concrete beneath. It’s important to proceed carefully to avoid gouging the surface.

Grinding and Sanding for Thin Epoxy Layers

For thinner layers of epoxy, grinding or sanding can be a viable method. Using a hand-held grinder or sander equipped with a diamond-tipped disc can effectively wear away the epoxy coating.

This method allows for a more controlled removal process. It minimizes the risk of damaging the underlying concrete. However, it’s recommended to seek professional assistance or advice to select the appropriate equipment and technique.

Renting and Operating a Concrete Floor Grinder

For larger areas or thicker layers of epoxy, renting a concrete floor grinder may be the most efficient method. These powerful machines are designed to grind away epoxy coatings. They will leave the concrete surface clean and ready for a new finish.

Floor grinders can be rented from most hardware stores or equipment rental centers. They come in various sizes to suit different project scales. It’s crucial to choose the right grinder and abrasive discs based on the epoxy’s hardness and the concrete’s condition.

The grinding process requires careful operation to evenly remove the epoxy without damaging the concrete. It may also require multiple passes with the machine. Proper ventilation and dust control measures are essential to managing the hazardous dust produced during grinding.

Regardless of the method chosen, it’s crucial to wear appropriate safety gear. They include gloves, masks, and eye protection to protect against dust and chemical exposure. Additionally, ensuring adequate ventilation and dust containment is crucial. This is to prevent the inhalation of harmful particles and maintain a safe working environment.

Chemical Methods for Epoxy Removal

The chemical methods involve the use of solvents or stripping solutions that break down the epoxy’s bond with the concrete. They allow for easier removal.

Here’s a guide on how to proceed with chemical methods for epoxy removal:

Choosing the Right Solvent or Stripping Solution

Identifying the most effective solvent is critical for efficiently breaking down the epoxy coating. Strong solvents such as acetone, denatured alcohol, or paint thinner are known for their effectiveness in quickly softening or dissolving epoxy.

For uncured epoxy, milder solutions like vinegar can be used to remove residues. It’s crucial to select a solvent that matches the type of epoxy you’re dealing with. This will ensure it can penetrate and loosen the adhesive without causing damage to the underlying surface.

Application Techniques for Chemical Removers

The application of chemical removers should be done with care to ensure the safety of the user and the integrity of the surface. It’s recommended to use a stiff-bristled brush or a mop to apply the solvent evenly across the epoxy coating. This will allow it to sit for the recommended period to effectively break down the bond.

For areas where the epoxy is particularly resistant, additional tools like a putty knife or a scraper may be needed to lift the softened epoxy from the surface. Always ensure proper ventilation and wear protective gear to avoid inhalation of toxic fumes or skin contact with the solvent.

Acid-Based Removal Processes

While acid-based removal methods can be effective for certain types of coatings, they are generally not recommended for epoxy removal due to the potential risks involved. Acids can be corrosive and pose significant health and safety hazards if not handled properly.

Therefore, it’s important to consider the nature of the epoxy and the surface it’s applied to before deciding on using acid-based processes. In most cases, opting for safer, non-acidic chemical removers is advisable.

Cleaning and Post-Removal Care

After the challenging task of removing epoxy flooring, ensuring the area is clean and safe is the next important step.

Here’s how to effectively manage the cleaning and care process post-removal:

Neutralizing Chemicals Post-Removal

Following the use of chemical removers or strippers to eliminate epoxy flooring, it’s crucial to neutralize any residual chemicals. This step is vital to safeguarding the area and preventing potential chemical reactions that could be harmful.

A recommended practice is to clean up chemical spills immediately. Epoxy flooring is quite resistant to stains and damage. But it can be affected by chemicals if not addressed promptly.

Utilizing a neutralizing agent and then washing the area with water is advised. Ensuring to remove excess liquid with a squeegee towards a drain will help maintain the safety and integrity of the space.

Restoring Concrete’s Shine After Epoxy Removal

Restoring the shine to a concrete floor post-epoxy removal can make it appear clean and well-maintained. A simple yet effective method is to use a cleaning solution made from diluted ammonia.

Mixing 2 to 3 ounces of ammonia with a gallon of hot water and applying it with a microfiber mop can clean the surface effectively. Moreover, this process will not leave streaks or a hazy build-up.

It’s essential to avoid using cleaning products that contain vinegar, citric acid, or are soap-based, as these can degrade the epoxy finish or leave a slippery residue. Regular cleaning with the right products will ensure the concrete maintains its appearance and safety.

When dealing with these post-removal care steps, always prioritize safety by wearing appropriate protective gear and ensuring good ventilation. Be extra careful when dealing with chemicals.

Professional Epoxy Removal Services

Opting for professional epoxy removal services can be a wise decision under certain circumstances.

When to Consider Hiring a Professional

Hiring a professional for epoxy flooring removal is recommended in several situations. If you’re dealing with a large area or if the removal process involves complex procedures that require specialized equipment or knowledge about handling hazardous chemicals, professional help is advisable.

Additionally, if the DIY approach seems overwhelming due to the labor intensity or technical aspects of the job, it’s time to call in the experts. Professionals have the experience, tools, and protective measures in place to handle the job efficiently and safely. They can help minimize the risk of damage to the concrete substrate and ensure a thorough removal.

Finding Reputable Epoxy Removal Services

To find a reputable service provider, start by looking for companies that specialize in epoxy coating removal for both commercial and residential properties. It’s beneficial to choose services that offer a broad range of epoxy-related services, including cleaning, repair, coating, and installation. These are indications of their comprehensive expertise in the field.

To find reputable services, you can search online platforms, check customer reviews, and ask for recommendations from people who have had similar work done. Always verify the credentials and insurance coverage of the service provider before hiring. Additionally, obtaining multiple quotes and asking for references can help you make an informed decision.

Preventative Measures and Maintenance

Ensuring your epoxy-coated floors remain neat and enduring involves adopting proactive measures and regular maintenance.

Here’s how to keep your floors looking their best and prevent future spills.

Tips for Preventing Future Epoxy Spills

- Product Selection for Epoxy Flooring: It is critical to be selective about the products used on epoxy flooring. Using harsh chemicals can lead to the deterioration of the epoxy coating. They will compromise its durability and appearance over time.

- Immediate Cleanup of Spills: Prompt action is essential in the event of spills on epoxy-coated floors. Immediate cleanup prevents stains and damage to the coating. It will ensure the floor retains its appearance and structural integrity.

Maintenance Advice for Epoxy-Coated Surfaces

Regular cleaning is key to maintaining the aesthetic appeal and longevity of epoxy-coated surfaces. For effective maintenance, here are some guidelines:

- Regular Sweeping: Sweep epoxy floors daily in commercial spaces or weekly in moderate-use residential spaces to remove foreign objects that could scratch or damage the floor. A microfiber dust mop is recommended for its effectiveness in trapping dirt.

- Washing with Water: Epoxy-coated floors should be washed weekly in commercial areas and monthly in residential garages. A regular string mop or a wet microfiber mop can be used to pick up debris while also cleaning the floors. Warm water is often sufficient for lifting and removing dirt.

- Using a Cleaner for Deep Cleans: For a deeper clean, consider a monthly or bimonthly cleanse with a pH-neutral concrete cleaner. This ensures the epoxy surface remains undamaged by harsh chemicals.

- Avoid Certain Cleaners: Citrus cleaners or vinegar should be avoided as they can degrade the epoxy coating over time. Similarly, soap-based cleaners can leave a residue that creates an opaque film over the shiny epoxy finish and can be slippery when wet.

How to Demo Epoxy Flooring FAQ

What Is the Best Method to Remove Epoxy From a Concrete Floor?

The best method depends on the specific circumstances of the epoxy flooring, such as its age, thickness, and the condition of the underlying concrete. Different types of epoxy flooring may require specific removal methods based on several factors.

These include their composition, application technique, and the condition of the underlying concrete. It’s important to assess the type of epoxy flooring and consult with professionals if unsure about the most effective removal method.

How Do I Safely Dispose of Epoxy Remnants After Removal?

This requires adherence to local regulations for hazardous waste. Since epoxy can contain chemicals harmful to the environment, it should not be disposed of with regular household waste. Contact your local waste management facility for guidelines on disposing of chemical residues and epoxy materials.

What Should I Do if I Accidentally Damage the Concrete While Removing Epoxy?

If the concrete is damaged during epoxy removal, it’s important to address the damage promptly to prevent further deterioration. Small cracks or chips can be filled with a concrete repair product.

For more significant damage, consulting with a professional concrete repair service is recommended to ensure the integrity of the floor is restored.

Why Not a Total Cleanout After Removing the Epoxy Flooring?

Removing epoxy flooring can be a complex task, leaving behind not just a clean slate but also unwanted remnants. While we at EZ CleanUp might not specialize in epoxy removal, our expertise in junk removal positions us perfectly to assist with the aftermath of your project.

From clearing out construction debris to hauling away the last bits of your renovation puzzle, we’ve got you covered. Or, you can tap into our services if you want to rent a dumpster.

Ready for a total cleanout? Reach out to us for seamless service that clears the path for your next big project.